Contact Us

E-Mail:

WhatsApp:

+86-18306398895

Tel:

Address:

Yuhuangling Industrial Park, Chengyang District, Qingdao, China

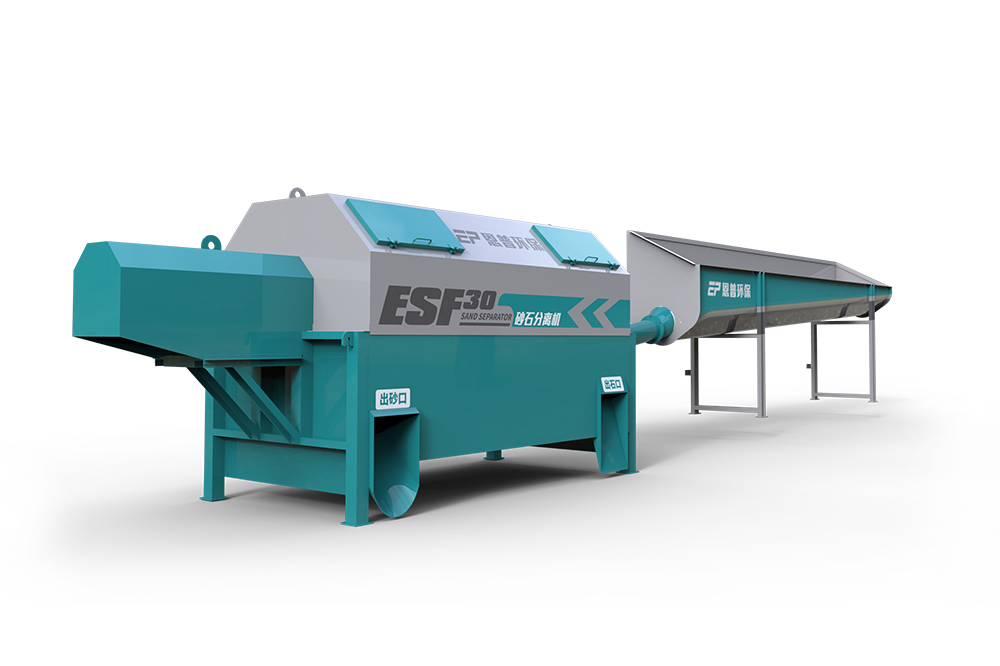

ESF30 Model Concrete Reclaimer

Structural features and working principle of ESF30 concrete reclaimer

Key words:

Key words:

Filter Press

Product Reference

Structural features and working principle of ESF30 concrete reclaimer

ESF30 concrete reclaimer mainly consists of eight parts, including guide chute, internal and external spiral sand screening drum, stone outlet chute, overflow chute, sprinkler pipe, drive system, water supply system and control system. When the residual concrete and water enter the guide chute, circulating water is continuously injected at the same time. Under the impact of the water flow, the mixed slurry and water enter the separator from the feed port to fully clean the residual concrete. Cement slurry water continuously flows out from the slurry outlet at the bottom of the separator and flows into the slurry pool through the guide chute. The washed sand and gravel fall into the material pool from the sand outlet and stone outlet respectively. The cement slurry water flowing from the slurry trough into the mixing tank is measured and reused with clean water in a specified proportion using the superposition method, achieving zero discharge and greatly saving resources.

Product Advantages

Workflow:

The ESF30 concrete reclaimer has two working modes, which the operator can select on the electric control cabinet.

1. Automatic mode: The working mode knob selects the automatic position

a) When the tank truck enters the site, the infrared photoelectric switch senses the concrete mixer truck, and the concrete reclaimer starts to rotate. After the concrete mixer truck arrives, the driver stops the car and manually presses the water filling button. The corresponding water filling pump A or water filling pump B (double parking space) fills the tank truck with water. When the two parking spaces are cleaning the tank truck, they do not interfere with each other and can also be carried out at the same time.

b) The water filling pump stops automatically after working for the set time, and the flushing pump at one end of the discharge flushing tank starts working. The operator injects the waste in the tank truck into the discharge flushing tank and flushes it into the concrete reclaimer.

c) The flushing pump stops working after the photoelectric switch shows that the tanker has left. If the tanker does not leave, the photoelectric switch keeps working, the flushing pump keeps working, and the concrete reclaimer does not stop; after the tanker leaves, the flushing pump stops working and the concrete reclaimer automatically enters the standby state.

The whole process is continuous and automatic, and the corresponding indicator light on the operation panel lights up for each step of the work. If the tanker enters the site continuously, the whole process will be automatically postponed. Add a fault sound and light alarm to the control cabinet, and people will know immediately if a fault occurs.

2. Manual mode: The working mode selects the manual position, and each step of the work needs to be completed by the operator on the operation panel. Each step of the work corresponds to a knob and a working indicator light.

(The manual mode is suitable for other ways of feeding materials, such as loaders, etc.). The order of manual operation is to turn on the concrete reclaimer, turn on the flushing pump, and put waste materials into the unloading flushing tank. After the separation is completed, start the spray pipe water pump to flush the screen, and manually stop after washing.

An emergency stop button is designed on the operation control cabinet. If an unexpected

situation is found on site, the operator only needs to press the button, and all actions of the entire system will be immediately powered off and stopped.

Advantages: a) Simple structure, easy maintenance and repair, the entire product function is all coaxial mechanical transmission, and maintenance and repair are simple.

b) The screen is a tapered fish scale hole, and the design of the high-pressure spray pipe can automatically clean the mesh blockage, which completely solves the blockage problem of the separator.

c) Low failure rate, all power of the equipment comes from a set of motor reducer;

d) High separation capacity, product drum diameter 1 meter, mud water separation capacity 30 tons/hour.

e) High cleanliness of separated materials, the lower 1/3 height of the separator is always full of water, that is, gravel and sand are washed with water, and the surface cleanliness is high.

The sand discharge mode is a filter water scoop type. Generally, the product screw conveyor squeezes out sand and contains a large amount of mortar.

f) The whole machine discharge loader shovels without interference

1. Automatic mode: The working mode knob selects the automatic position

a) When the tank truck enters the site, the infrared photoelectric switch senses the concrete mixer truck, and the concrete reclaimer starts to rotate. After the concrete mixer truck arrives, the driver stops the car and manually presses the water filling button. The corresponding water filling pump A or water filling pump B (double parking space) fills the tank truck with water. When the two parking spaces are cleaning the tank truck, they do not interfere with each other and can also be carried out at the same time.

b) The water filling pump stops automatically after working for the set time, and the flushing pump at one end of the discharge flushing tank starts working. The operator injects the waste in the tank truck into the discharge flushing tank and flushes it into the concrete reclaimer.

c) The flushing pump stops working after the photoelectric switch shows that the tanker has left. If the tanker does not leave, the photoelectric switch keeps working, the flushing pump keeps working, and the concrete reclaimer does not stop; after the tanker leaves, the flushing pump stops working and the concrete reclaimer automatically enters the standby state.

The whole process is continuous and automatic, and the corresponding indicator light on the operation panel lights up for each step of the work. If the tanker enters the site continuously, the whole process will be automatically postponed. Add a fault sound and light alarm to the control cabinet, and people will know immediately if a fault occurs.

2. Manual mode: The working mode selects the manual position, and each step of the work needs to be completed by the operator on the operation panel. Each step of the work corresponds to a knob and a working indicator light.

(The manual mode is suitable for other ways of feeding materials, such as loaders, etc.). The order of manual operation is to turn on the concrete reclaimer, turn on the flushing pump, and put waste materials into the unloading flushing tank. After the separation is completed, start the spray pipe water pump to flush the screen, and manually stop after washing.

An emergency stop button is designed on the operation control cabinet. If an unexpected

situation is found on site, the operator only needs to press the button, and all actions of the entire system will be immediately powered off and stopped.

Advantages: a) Simple structure, easy maintenance and repair, the entire product function is all coaxial mechanical transmission, and maintenance and repair are simple.

b) The screen is a tapered fish scale hole, and the design of the high-pressure spray pipe can automatically clean the mesh blockage, which completely solves the blockage problem of the separator.

c) Low failure rate, all power of the equipment comes from a set of motor reducer;

d) High separation capacity, product drum diameter 1 meter, mud water separation capacity 30 tons/hour.

e) High cleanliness of separated materials, the lower 1/3 height of the separator is always full of water, that is, gravel and sand are washed with water, and the surface cleanliness is high.

The sand discharge mode is a filter water scoop type. Generally, the product screw conveyor squeezes out sand and contains a large amount of mortar.

f) The whole machine discharge loader shovels without interference

Product Parameters

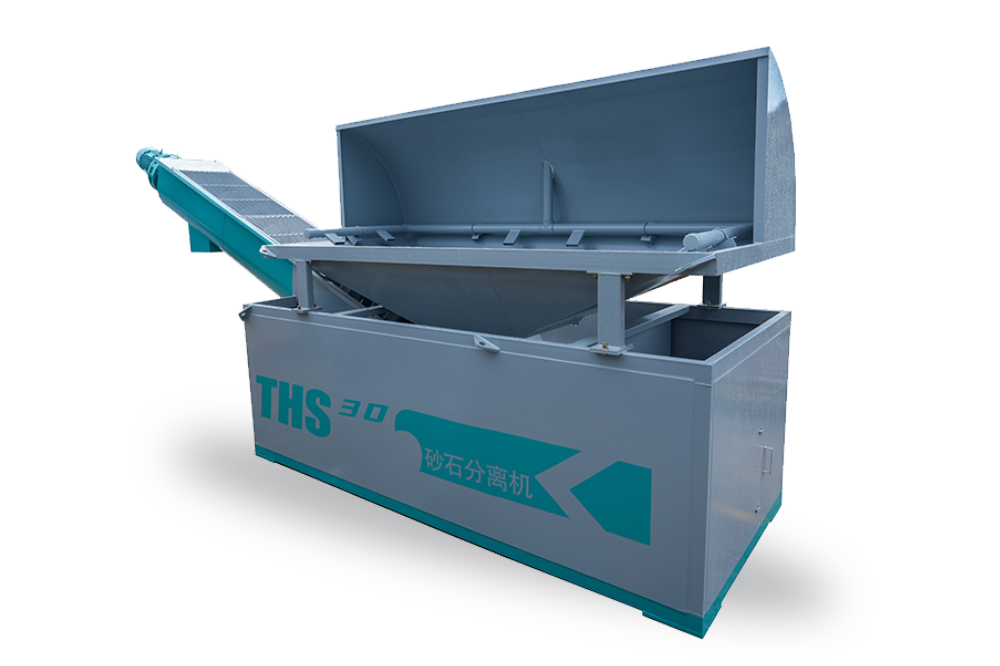

| ltem | Unit | Date | |||

| Product Model | - | THS10 | THS20 | ZSF30 | ESF30 |

| Screening Capability | t/h | 10-20 | 20-30 | 30-40 | 30 |

| Stone size Screened | mm | - | >φ5 | >φ5 | >φ5 |

| Sand size Screened | mm | - | φ1-φ5 | φ1-φ5 | φ1-φ5 |

| Mixing Trucks Number | Qty | <10 | 10-30 | >30 | <20 |

| Power of main Body | kw | 7.5 | 7 | 5.5 | 4 |

| Weight of main body | kg | 2000 | 5000 | 4000 | 3000 |

| Dimensions(LxWxH) | mm | 6660x1200x3100 | 6360x1750x2600 | 4680x2220x2290 | 4500x1700x2190 |

Get Quote

Note: Please leave your contact information and our professionals will contact you as soon as possible!