Contact Us

E-Mail:

WhatsApp:

+86-18306398895

Tel:

Address:

Yuhuangling Industrial Park, Chengyang District, Qingdao, China

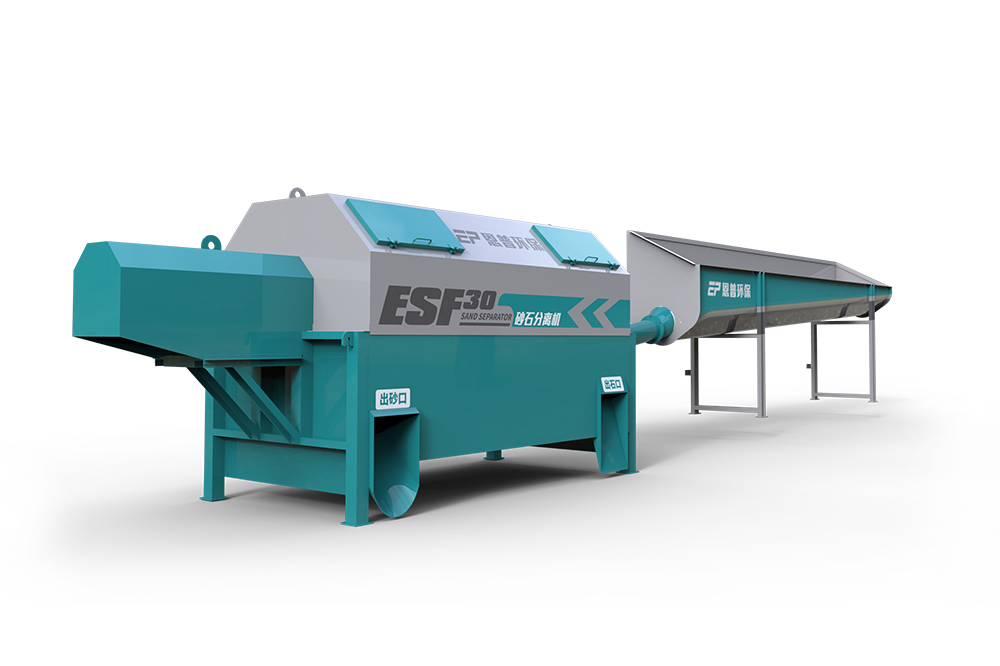

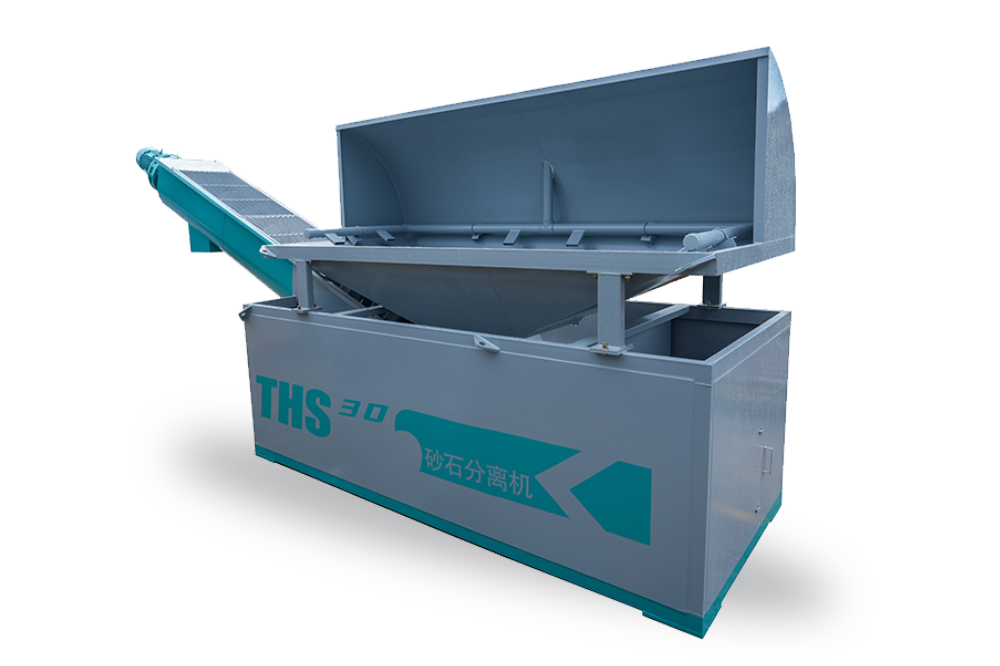

THS30 Model Concrete Reclaimer

Concrete reclaimers play a vital role in the construction industry. As a supplier of concrete reclaimers, we provide valuable solutions for construction sites that want to reduce waste and improve sustainability.

Key words:

Key words:

Filter Press

Product Reference

1. Equipment Purpose

Concrete reclaimers play a vital role in the construction industry. As a supplier of concrete reclaimers, we provide valuable solutions for construction sites that want to reduce waste and improve sustainability.

The role of concrete reclaimers is to collect, recycle and reuse leftover concrete from construction sites, reducing the amount of waste generated. This not only helps save money, but also promotes environmental responsibility and sustainability. By being able to recycle clean concrete to the construction site, concrete reclaimers can reduce the amount of new material required for each project, making construction more cost-effective and environmentally friendly.

2. Workflow:

The concrete reclaimer has two working modes (automatic mode and manual mode), and the operator can select them by turning the knob on the large electric control cabinet.

Structural features and working principle of THS30 concrete reclaimer THS30 sewage treatment system is a kind of equipment that washes and separates sand, gravel and mortar and reuses the mortar. Its working device consists of six parts: sand and gravel spiral, overflow port, sprinkler pipe, drive system, water supply system and control system.

1. Automatic mode:

The working mode knob selects the automatic position - tanker washing mode a) After the tanker enters the site, the driver stops the car and manually presses the [Tanker Washing] button. The corresponding water pump and sewage pump work to add water to the tanker.

b) The water pump stops automatically after working for the set time. After the water pump stops, the sand output screw starts working. The operator injects the waste in the tanker into the sewage bucket above the sewage bucket. The cleaned sand and gravel enter the spiral sewage bucket below and enter the sand and gravel bin through the sand output screw;

c) The water pump stops automatically after working for the set time. At the same time, the flushing pump above the spiral starts working. The operator injects the waste in the tanker into the unloading flushing tank and flushes it into the concrete reclaimer;

The whole process is continuous and automatic, and the corresponding indicator light on the operation panel lights up for each step of the work. If the tanker enters the site continuously, the whole process will be automatically postponed.

2. Manual mode:

The working mode is selected in manual position. Each step of the work needs to be completed by the operator on the operation panel. Each step of the work corresponds to a knob and a working indicator light. After the separation is completed, the machine is manually stopped and the knob switch is turned to the automatic state.

An emergency stop button is designed on the operation control cabinet. If an unexpected situation is found on site, the operator only needs to press the button, and all actions of the entire system will be immediately powered off and stopped.

Concrete reclaimers play a vital role in the construction industry. As a supplier of concrete reclaimers, we provide valuable solutions for construction sites that want to reduce waste and improve sustainability.

The role of concrete reclaimers is to collect, recycle and reuse leftover concrete from construction sites, reducing the amount of waste generated. This not only helps save money, but also promotes environmental responsibility and sustainability. By being able to recycle clean concrete to the construction site, concrete reclaimers can reduce the amount of new material required for each project, making construction more cost-effective and environmentally friendly.

2. Workflow:

The concrete reclaimer has two working modes (automatic mode and manual mode), and the operator can select them by turning the knob on the large electric control cabinet.

Structural features and working principle of THS30 concrete reclaimer THS30 sewage treatment system is a kind of equipment that washes and separates sand, gravel and mortar and reuses the mortar. Its working device consists of six parts: sand and gravel spiral, overflow port, sprinkler pipe, drive system, water supply system and control system.

1. Automatic mode:

The working mode knob selects the automatic position - tanker washing mode a) After the tanker enters the site, the driver stops the car and manually presses the [Tanker Washing] button. The corresponding water pump and sewage pump work to add water to the tanker.

b) The water pump stops automatically after working for the set time. After the water pump stops, the sand output screw starts working. The operator injects the waste in the tanker into the sewage bucket above the sewage bucket. The cleaned sand and gravel enter the spiral sewage bucket below and enter the sand and gravel bin through the sand output screw;

c) The water pump stops automatically after working for the set time. At the same time, the flushing pump above the spiral starts working. The operator injects the waste in the tanker into the unloading flushing tank and flushes it into the concrete reclaimer;

The whole process is continuous and automatic, and the corresponding indicator light on the operation panel lights up for each step of the work. If the tanker enters the site continuously, the whole process will be automatically postponed.

2. Manual mode:

The working mode is selected in manual position. Each step of the work needs to be completed by the operator on the operation panel. Each step of the work corresponds to a knob and a working indicator light. After the separation is completed, the machine is manually stopped and the knob switch is turned to the automatic state.

An emergency stop button is designed on the operation control cabinet. If an unexpected situation is found on site, the operator only needs to press the button, and all actions of the entire system will be immediately powered off and stopped.

Product Advantages

Advantages:

a) Simple structure, small footprint, suitable for sites with tight space and sand and gravel do not need to be separated.

b) The overall open structure design of the screen, the external spiral motor, high safety, convenient and quick use and maintenance.

c) Low failure rate, all power of the equipment comes from a set of motor reducers.

d) Large-capacity sewage bucket design, the washed sand and gravel are cleaner and more

thorough. Suitable for tank washing trucks and a small amount of residual waste at mixing stations e) Free placement according to the site, flexible layout.

b) The overall open structure design of the screen, the external spiral motor, high safety, convenient and quick use and maintenance.

c) Low failure rate, all power of the equipment comes from a set of motor reducers.

d) Large-capacity sewage bucket design, the washed sand and gravel are cleaner and more

thorough. Suitable for tank washing trucks and a small amount of residual waste at mixing stations e) Free placement according to the site, flexible layout.

Product Parameters

| Item | parameter |

| Sand and gravel slurry water treatment capacity | 30T/h |

| Sand particle size | ≥1mm |

| Stone particle size | ≥5mm |

| Dimensions | 7100mm*1850mm*2900mm |

| Machine power | 7.5KW |

| Machine weight | 3t |

Get Quote

Note: Please leave your contact information and our professionals will contact you as soon as possible!