Contact Us

E-Mail:

WhatsApp:

+86-18306398895

Tel:

Address:

Yuhuangling Industrial Park, Chengyang District, Qingdao, China

HSF50s Model Concrete Reclaimer

Structural features and working principle of HSF50S concrete reclaimerHSF50S sewage treatment system

Key words:

Key words:

Filter Press

Product Reference

Structural features and working principle of HSF50S concrete reclaimer

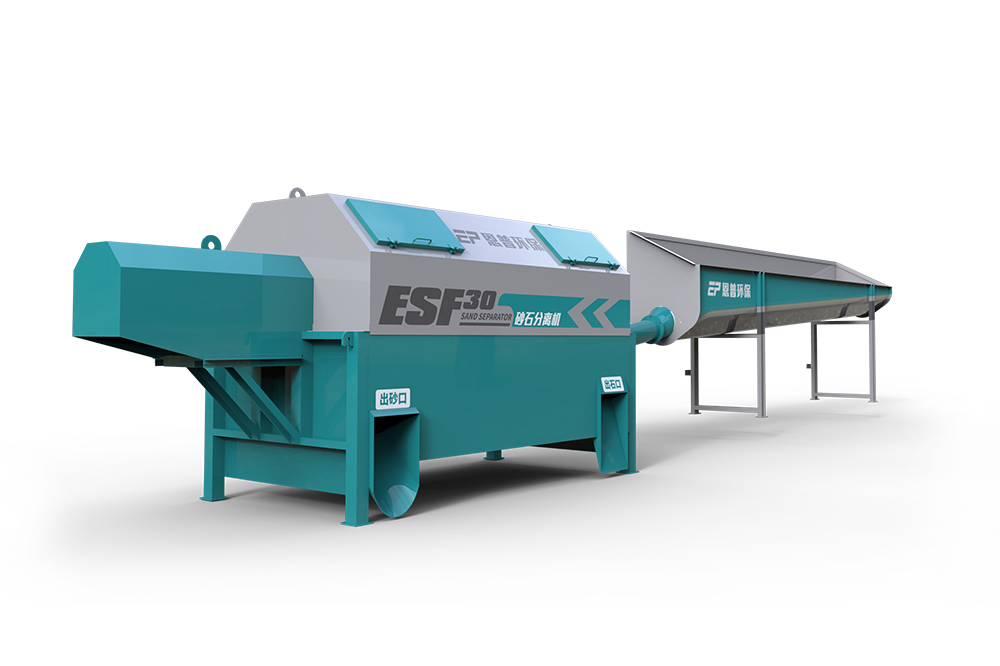

HSF50S sewage treatment system is a kind of equipment that washes and separates sand, gravel and mortar and reuses the mortar. Its working device consists of eight parts: linear vibrating screen, fine sand recovery machine, discharge trough, spray pipe, drive system, water supply system, mixing system and control system.

The concrete reclaimer has two working modes (automatic mode and manual mode), and the operator can select them by turning the knob on the large electric control cabinet.

Automatic mode:

1. The working mode knob selects the automatic position - tank car washing mode

1) After the tank car enters the site, the driver stops the car and manually presses the [Tank Car Washing] button. The corresponding sewage pump A works to add water to the tank car.

2) The water pump stops automatically after working for the set time. After the water pump stops, the flushing chute water pump B, the linear vibrating screen, and the fine sand recovery machine vibration motor start working at the same time. The operator injects the waste in the tank car into the discharge trough. The washed sand passes through the vibrating screen and enters the first sedimentation tank below. The sewage is pumped into the cyclone through the slurry pump. The sewage enters the sewage bucket of the fine sand recovery machine box, and then the sewage overflows back to the first sedimentation tank after the cyclone washing. The fine sand is transported to the sand bin through the vibrating screen of the fine sand recovery machine. The gravel passes through the continuously vibrating horizontal linear screen and finally enters the gravel material yard.

2. Select the automatic position of the working mode knob - concrete washing mode

If there is a large amount of waste material in the tank truck or forklift that needs to be washed, you need to manually start the [Concrete Washing] button switch for washing waste material before putting the material in, and the flushing discharge trough water pump, the vibrating screen sewage spray water pump, the vibrating screen clean water spray water pump, the linear vibrating screen, and the fine sand recovery machine vibration motor will work at the same time. When there is no residual material on the vibrating screen, manually turn off the [Concrete Washing] button switch, the flushing discharge trough water pump and the vibrating screen sewage spray water pump will stop automatically, and then the vibrating screen clean water spray water pump, the linear vibrating screen and the fine sand recovery machine vibration motor will stop running with a delay.

Manual mode:

The working mode selects the manual position, and each step of the work needs to be completed by the operator on the operation panel, and each step of the work corresponds to a knob and a working indicator light. The order of manual operation is to manually start the vibrating screen, start the fine sand recovery machine, turn on the spray pump on the linear vibrating screen and the discharge trough flushing pump, put waste material into the receiving trough, manually stop after separation, and turn the knob switch to the automatic state.

Product Advantages

Advantages

a) Easy-to-install product design, with no slope design, convenient and quick operation and maintenance.

b) Efficient car washing system, can wash 2 cars at the same time.

c) Unique vibrating screen design, the screen is not easy to clog, and the separation is more thorough.

d) Double cyclone high-speed separation system, which can effectively separate fine sand and slurry water.

e) It can be placed freely according to the site and arranged flexibly.

b) Efficient car washing system, can wash 2 cars at the same time.

c) Unique vibrating screen design, the screen is not easy to clog, and the separation is more thorough.

d) Double cyclone high-speed separation system, which can effectively separate fine sand and slurry water.

e) It can be placed freely according to the site and arranged flexibly.

Product Parameters

| Item | Parameter |

| Sand and gravel slurry water treatment capacity | 50T/h |

| Stone vibrating screen | ZSG-1237 |

| Sand particle size | ≥1mm |

| Stone particle size | ≥5mm |

| Double cyclone | 350 type + 250 type |

| Machine power | 14.3KW |

Get Quote

Note: Please leave your contact information and our professionals will contact you as soon as possible!