Contact Us

E-Mail:

WhatsApp:

+86-18306398895

Tel:

Address:

Yuhuangling Industrial Park, Chengyang District, Qingdao, China

Medium-scale asphalt mixing plant

With innovative design, our asphalt mixing plant are produced through intelligent, refined and specialized production. Professional services are offered. Different models from CL2000 、 CL3000

and full range of types are available.

Key words:

Key words:

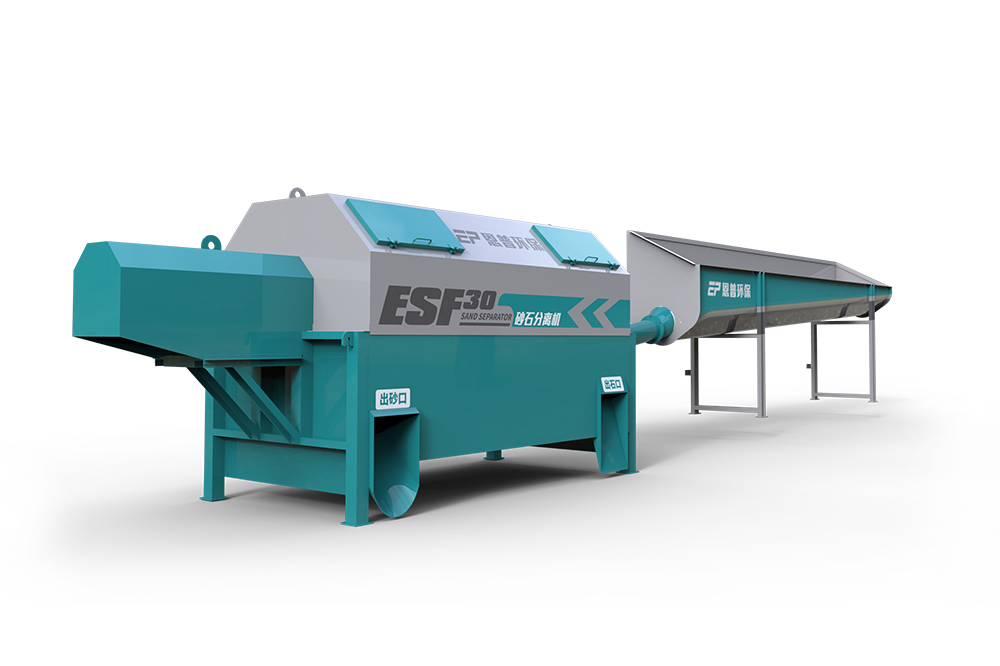

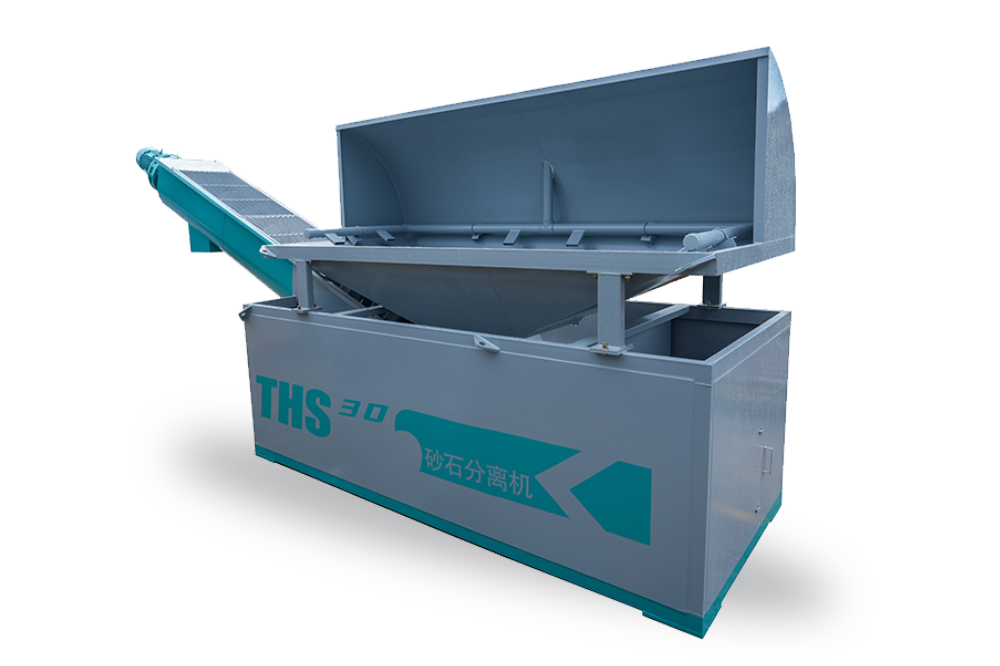

Filter Press

Product Reference

With innovative design, our asphalt mixing plant are produced through intelligent, refined and specialized production. Professional services are offered. Different models from CL2000 、 CL3000

and full range of types are available.

This equipment has obtained several patented technologies, such as control technology, weighing technology, integrated multi-fuel combustion technology, and RAP technology. It has stable performance and is environmentally friendly.

This equipment has obtained several patented technologies, such as control technology, weighing technology, integrated multi-fuel combustion technology, and RAP technology. It has stable performance and is environmentally friendly.

Product Advantages

1.Modular design. Hot elevator and filler elevator are combined with the main tower, which makes the installation and relocation more convenient

2.It adopts parallel subtraction weighing technology, which makes aggregate weighing more accurate and oil-to aggregate ratio more stable

3.Vibrating screen can fine sieve out 6 kinds of aggregates, which makes ingredient more accurate and stable

4.2-stage dust cleaning system and rotating blowback technology make emission comply with Europe standard

5.Europe combustion technology and drying system are perfectly combined, which realizes less power consumption and less emission

6.The control system adopts industrial Ethernet and CC-Link bus technology, which makes data transmission stable and fast

2.It adopts parallel subtraction weighing technology, which makes aggregate weighing more accurate and oil-to aggregate ratio more stable

3.Vibrating screen can fine sieve out 6 kinds of aggregates, which makes ingredient more accurate and stable

4.2-stage dust cleaning system and rotating blowback technology make emission comply with Europe standard

5.Europe combustion technology and drying system are perfectly combined, which realizes less power consumption and less emission

6.The control system adopts industrial Ethernet and CC-Link bus technology, which makes data transmission stable and fast

Product Parameters

| Мodel | CL-2000 | CL-3000 | |

| Rated productivity(in standard condition) | 160 T/H | 240 T/H | |

| Installed power | 480KW | 630KW | |

| Cold aggregate bin | Quantity×Capacity | 5×11 m3 | 6×11 m3 |

| Drying roller capacity | Diameter×Length(mm) | Ø1980x8500 | Ø2550x9420 |

| Dust cleaning system | Filtering area | 750 m2 | 1035 m2 |

| Hot elevator | Elevator capacity | 180 T/H | 260 T/H |

| Filler elevator | Elevator capacity | 26 T/H | 37 T/H |

| Vibrating screen | Structure | 5 decks 9 segments | 6 decks(8 decks optional) |

| Hot elevator | Capacity | 40 m3 | 60 m3 |

| Aggregate scale silo | Scale range | 1-2500kg | 1-3500kg |

| Scale accuracy | ≤±0.4% | ≤±0.4% | |

| Bitumen scale silo | Scale range | 1-200kg | 1-300kg |

| Scale accuracy | ≤±0.2% | ≤±0.2% | |

| Filler silo | Scale range | 1-260kg | 1-400kg |

| Scale accuracy | ≤±0.2% | ≤±0.2% | |

| Mixer | Capacity | 2000kg | 3000kg |

| Bitumen supplying system | шт. × м3 | 2x50 m3 | 3x50 m3 |

| Thermal conducting oil boiler | Thermal capacity | 800 000 Kcal/h | 1 000 000 Kcal/h |

| Hot mix storage silo | Capacity | 80T | 120T |

| (optional) | |||

Get Quote

Note: Please leave your contact information and our professionals will contact you as soon as possible!